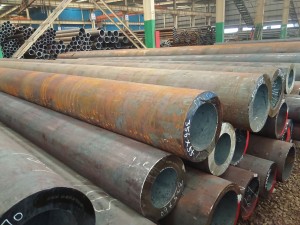

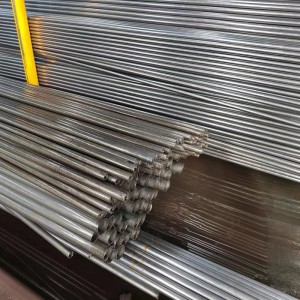

SAE4340 40CrNiMoA Alloy Seamless Steel Pipe

Short Description:

40CrNiMoA alloy seamless steel pipe is a high-strength, high-toughness alloy structural steel pipe. Its composition mainly includes chromium, nickel, molybdenum and a small amount of carbon, silicon, manganese and other elements, through specific proportions and heat treatment processes, it has good corrosion resistance and high temperature performance. Due to its excellent mechanical properties and wide range of application fields, it has been widely used in many industries.