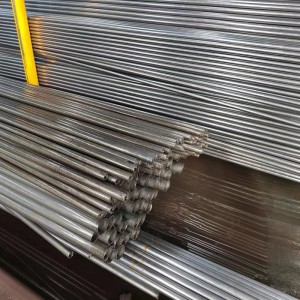

High quality 12Cr1MoV High Pressure Boiler Seamless Steel Pipe

Short Description:

This Alloy Steel Pipe with 12cr1MOV Material is a seamless steel pipe that can be used in petroleum, chemical, electric power and boiler applications. It has the characteristics of cold resistance, heat resistance and corrosion resistance.12Cr1MoV is a kind of alloy pipe. The main purpose is to make steel structural parts in the boiler.

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for High quality 12Cr1MoV High Pressure Boiler Seamless Steel Pipe, “Change for that improved!” is our slogan, which means “A better globe is before us, so let’s take pleasure in it!” Change for the better! Are you all set?

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for China 12Cr1MoV High Pressure Boiler Tube, We’ve got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any complete acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The service temperature is 580 ℃, and the steel plate is required to have high high temperature endurance strength. The steel plate is delivered in the normalized and tempered state. 12Cr1MoVG alloy pipe is based on high-quality carbon structural steel, and one or several alloy elements are appropriately added to improve the mechanical properties, toughness and hardenability of the steel. Products made of such steel usually require heat treatment (normalizing or quenching and tempering); The parts and components made of them usually need to undergo quenching and tempering or surface chemical treatment (carburizing, nitriding, etc.), surface quenching or high-frequency quenching before use. Therefore, according to different chemical compositions (mainly carbon content), heat treatment processes and applications, such steels can be roughly divided into carburized, Quenched and tempered and nitrided steels.

First, it can be 100% recycled, energy-saving and environmental protection.

Second, it has extremely high plasticity and can be used for secondary production and processing.

Third, it has good thermal conductivity and high temperature creep ability.

Fourth, it has good oxidation resistance and corrosion resistance.

Fifth, it has good cold and hot processing performance.

12Cr1MoVG is a kind of chromium molybdenum alloy steel pipe, in which the main chemical components are carbon 0.08-0.15, silicon 0.17-0.37, manganese 0.40-0.70, phosphorus not more than 0.035, sulfur not more than 0.035, chromium 0.90-1.20, molybdenum 0.25-0.35, alum 0.15-0.30, etc.

First, it is mainly used to manufacture high-pressure alloy tubes for heating surfaces of water tube boilers with high pressure and above.

Second, it is widely used in superheaters, headers and main steam ducts of domestic high-pressure, ultra-high pressure and subcritical power station boilers.

Third, large diameter pipes are mainly used as headers and Main Steam Conduits with steam parameters below 565 ℃.

First, hot rolling (extrusion seamless steel pipe) process flow:

Round tube billet → heating → piercing → three roll cross rolling, continuous rolling or extrusion → pipe stripping → sizing (or reducing) → cooling → billet → straightening → hydrostatic test (or flaw detection) → marking → warehousing.

Second, cold drawing (rolling) seamless steel pipe process flow:

Round tube billet → heating → piercing → heading → annealing → pickling → oil coating (copper plating) → multi pass cold drawing (cold rolling) → billet tube → heat treatment → straightening → hydrostatic test (or flaw detection) → marking → warehousing.

|

Elements |

Data |

|

Carbon |

0.08-0.15 |

|

Silicon |

0.17-0.37 |

|

Manganese |

0.40-0.70 |

|

Phosphorus(max) |

≤0.030 |

|

Sulfur(max) |

≤0.030 |

|

Chromium |

0.90-1.20 |

|

Molybdenum |

0.25-0.35 |

|

Cuprum(max) |

≤0.20 |

|

Nickel(max) |

≤0.30 |

|

Vanadium(max) |

0.15-0.30 |

|

Yield Strength (Mpa) |

470-640 |

|

Tensile Strength (Mpa) |

255 |

|

Elongation (%) |

21 |

|

W.T.(S) |

Tolerance of W.T. |

|

|

<3.5 |

+15%(+0.48mm min) |

|

|

-10%(+0.32mm min) |

||

|

3.5-20 |

+15%,-10% |

|

|

>20 |

D<219 |

±10% |

|

D≥219 |

+12.5%,-10% |

|

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services.

High quality 12Cr1MoV High Pressure Boiler Seamless Steel Pipe

“Change for that improved!” is our slogan, which means “A better globe is before us, so let’s take pleasure in it!” Change for the better! Are you all set?

China 12Cr1MoV High Pressure Boiler Tube

We’ve got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any complete acknowledge. Free samples may be delivered and company check out to our corporation. Hope to get inquiries type you and construct a long-term co-operation partnership.