High Quality High Standard Precision Cold Rolled Seamless Steel Pipe and Tube

Short Description:

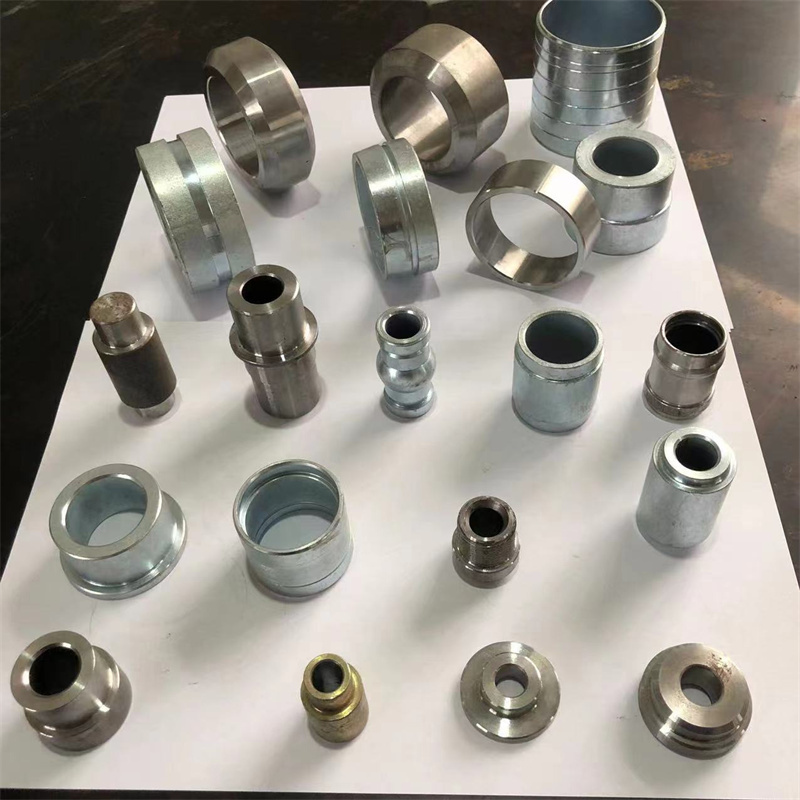

Precision steel pipe is a kind of high-precision steel pipe material after cold drawing or hot rolling. Precise steel pipes are mainly used to produce products of pneumatic or hydraulic components, such as cylinders or oil cylinders, due to their advantages such as no oxide layer on the inner and outer walls, no leakage under high pressure, high precision, high finish, no deformation during cold bending, flaring, flattening and no cracks The precision steel pipe has high dimension accuracy, high internal and external surface finish, no oxide film on the internal and external surfaces of the steel pipe after heat treatment, no crack on the expanded and flattened steel pipe, no deformation during cold bending, and can withstand high pressure, and can be used for various complex deformation and deep mechanical processing.

Haihui steel pipe is specialized in custom production of high quality seamless steel tubes under international standards ASTM A519, ASTM A106, ASTM A500, ASME SA500, DIN2391, DIN1629, EN10305-1, DIN17121, EN10297-1, JIS3441, JIS3444 and JIS3445. We provide small batch customization service, especially for small and medium-size enterprises. Raw material, internal and external dimensional tolerances and consistency, internal and external surface roughness, straightness, mechanical properties, eccentricity, special shape, alloy steel, small-diameter thick-walled seamless steel tubes all can be customized. The production range for outer diameter is from 10 to 120mm and for wall thickness is from 1 to 20mm.

Each individual member from our large performance revenue crew values customers’ needs and company communication for High Quality High Standard Precision Cold Rolled Seamless Steel Pipe and Tube, We think this sets us apart from the competition and makes customers choose and trust us. We all wish to develop win-win deals with our prospects, so give us a connect with today and make a new good friend!

Each individual member from our large performance revenue crew values customers’ needs and company communication for ASTM A1020/1045/ST52/ST37 Seamless Steel Pipe, Should really any of those items be of curiosity for you, you should allow us to know. We’ll be satisfied to give you a quotation on receipt of one’s thorough specs. We now have our personal experienced R&D enginners to meet any of one’s requriements, We appear forward to receiving your enquires soon’and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

The special-shaped steel pipe can be divided into elliptical special-shaped steel pipe, triangular special-shaped steel pipe, hexagonal special-shaped steel pipe, rhombic special-shaped steel pipe, octagonal special-shaped steel pipe, semicircular special-shaped steel pipe, unequal hexagonal special-shaped steel pipe, five petal quincunx special-shaped steel pipe, biconvex special-shaped steel pipe, double concave special-shaped steel pipe, melon shaped special-shaped steel pipe, conical special-shaped steel pipe and corrugated special-shaped steel pipe.

1. Performance index analysis of special-shaped steel pipe – plasticity

Plasticity refers to the ability of metal materials to produce plastic deformation (permanent deformation) without damage under load.

2. Performance index analysis of special-shaped steel pipe – hardness

Hardness is a pointer to measure the hardness of metal materials. The most commonly used method for measuring hardness in production is the indentation hardness method, which is to use an indenter with a certain geometry to press into the surface of the tested metal material under a certain load, and determine its hardness value according to the degree of indentation.

Commonly used methods include Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV).

3. Performance index analysis of special-shaped steel pipe – fatigue

The strength, plasticity and hardness discussed above are all indicators of mechanical properties of metals under static load. In fact, many machine parts work under cyclic load, and under this condition, fatigue will occur.

4. Performance index analysis of special-shaped steel pipe – impact toughness

The load acting on the machine at a great speed is called impact load, and the ability of metal to resist damage under impact load is called impact toughness.

5. Performance index analysis of special-shaped steel pipe – strength

Strength refers to the resistance of metal materials to failure (excessive plastic deformation or fracture) under static load. Since the action modes of load include tension, compression, bending and shear, the strength is also divided into tensile strength, compressive strength, bending strength and shear strength. There is often a certain connection between various strengths. Generally, tensile strength is the most basic strength indicator in use.

|

C, % |

Si, % |

Mn, % |

P, % |

S, % |

Cr, % |

Ni, % |

Cu, % |

|

| 10# |

0.07-0.13 |

0.17-0.37 |

0.35-0.65 |

0.025 max |

0.025 max |

0.15 max |

0.30 max |

0.25 max |

|

C, % |

Si, % |

Mn, % |

P, % |

S, % |

Cr, % |

Ni, % |

Cu, % |

|

| 20# |

0.17-0.23 |

0.17-0.37 |

0.35-0.65 |

0.025 max |

0.025 max |

0.25 max |

0.30 max |

0.25 max |

|

C, % |

Si, % |

Mn, % |

P, % |

S, % |

Cr, % |

Ni, % |

Cu, % |

|

| 45# |

0.42-0.50 |

0.17-0.37 |

0.50-0.80 |

0.025 max |

0.025 max |

0.25 max |

0.30 max |

0.25 max |

|

C, % |

Si, % |

Mn, % |

P, % |

S, % |

Cr, % |

Ni, % |

Cu, % |

|

| Q345 |

0.24 max |

0.55 max |

1.60 max |

0.025 max |

0.025 max |

0.30 max |

0.30 max |

0.40 max |

Each individual member from our large performance revenue crew values customers’ needs and company communication for Personlized Products High Quality High Standard Precision Cold Rolled Seamless Steel Pipe and Tube, We think this sets us apart from the competition and makes customers choose and trust us. We all wish to develop win-win deals with our prospects, so give us a connect with today and make a new good friend!

Personlized Products China Seamless Steel Pipe and Tube and High Quality High Standard, Should really any of those items be of curiosity for you, you should allow us to know. We’ll be satisfied to give you a quotation on receipt of one’s thorough specs. We now have our personal experienced R&D enginners to meet any of one’s requriements, We appear forward to receiving your enquires soon’and hope to have the opportunity to work together with you in the future. Welcome to check out our company.